KUMAR METAL INDUTRIES P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to KUMAR METAL INDUTRIES P.LTD.

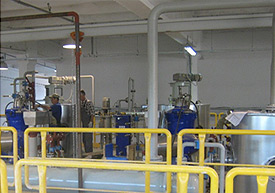

Degumming And Neutralizing

Degumming & Neutralizing: Crude oil is delivered to the system by the Feed Pump. It is heated to 65 - 70 C in the Crude Oil Economizer by hot oil from down-stream bleaching/deodorizing operations or, when necessary, by steam in the Feed Heater mixed with pre calculated quantity of Phosphoric acid in a gum conditioning mixer the pre calculated quantity of water is added . Oil water mixture is fed to hydration tank to give sufficient residence time for gums to agglomerate on hydration. This oil is then pumped to separator where the oil and hydrated gums are separated and pumped to storage or disposal or gum drying plant in case of soybean gums.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.